Ai 2L R Series Single Jacketed Glass Reactor

| SKU | Description | Jacket | Electrical | Quantity | Price | Add to Cart |

|---|---|---|---|---|---|---|

| R02.115 | Ai R Series 2L Jacketed Glass Reactor | Single | 115V, 50/60Hz | 1 Each |

|

|

| R02.220 | Ai R Series 2L Jacketed Glass Reactor | Single | 220V, 50/60Hz | 1 Each |

|

Description

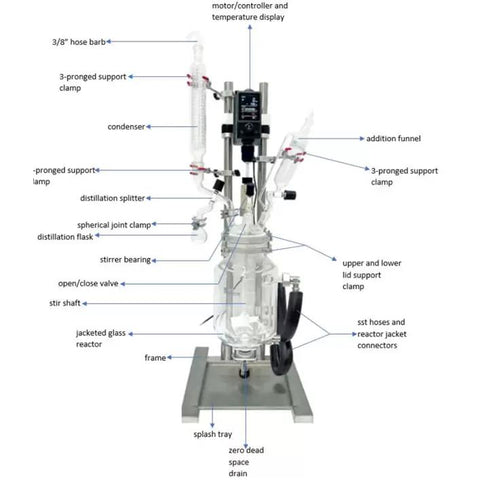

Introducing the Ai R-series single glass reactors bench top reactors. Both the 2L and 5L reactor vessels can be used on the same frame, allowing for greater flexibility and customizability. Reactors are designed for synthetic reaction of different types of materials in a controlled temperature and vacuum environment. Each reactor features adjustable stirring speeds and a constant pressure feeding funnel that allows you to add material to the vessel at a uniform and controlled speed. The built-in condenser makes it possible to recover some materials, also at a controlled rate of speed.

Features

- Solvent-resistant PTFE on all sealing components ensures long time durability and operation.

- All glassware is hand-made from food grade high borosilicate glass that is corrosion-resistant.

- Adjustable stirring rate provides great torque or high speed.

- Wide range of temperature operations, from -120C to -200C.

- Large condenser cooling surface for exceptional condensation performance.

- Rugged stainless steel reinforced PTFE stirrer with anchored agitator, suitable for a wide range of viscous materials.

- Visual operation with digital speed and temperature displays.

- Easy swap between 2L and 5L capacity (additional vessel required, not included)

- One year warranty and US-based parts, service, and support.

Your safety is important to us! Please use caution when operating. Users of glass reaction equipment must take all necessary precautions to avoid contact with rotating parts, particularly the entanglement of loose clothing, hair, necklaces, or other jewelry. Under these circumstances, the winding action of the rotating parts can draw the user(s) into the apparatus, resulting in the breakage of glassware, burns, and/or chemical exposure. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Specifications

| Model | R02 |

|---|---|

| Electrical Requirement | 115V-230V, 50/60Hz |

| Power Output | 70W |

| Environmental Conditions | Temperature 5-40C Max. relative humidity 80% for temperatures up to 30ᵒC decreasing linearly to 50 % relative humidity at 40ᵒC Mains supply volt fluctuations up to ±10 % of the nominal voltage Transient overvoltage up to the levels of overvoltage category II (See Note 1). Temporary overvoltage occurring on the mains supply. Applicable pollution degree of the intended environment (pollution degree 2 in most cases (See Note 2). Note 1: These levels of transient overvoltage are typical for equipment supplied from the building wiring. Note 2: Manufacturers may specify more restricted environmental conditions for operation, nevertheless the equipment must be safe within these normal environmental conditions. |

| Glass Vessel Temperature Range | From -120ᵒC to 200ᵒC |

| Cooling/Heating Jacket Capacity | 1.38L |

| Maximum Jacket Pressure | 0.08 MPa |

| Vacuum Gauge | Mechanical |

| Vacuum Level | 300 torr |

| Vacuum Sealinge | PTFE |

| Rotation Controller | Located on the motor itself |

| Temperature Display | Located on the motor itself |

| Reaction Glass Vessel Capacity | 2L |

| Agitator | 4-blades with a 45-degree pitch |

| Glass Material | High borosilicate glass 303 |

| Vessel Head | Domed with 5 ports |

| Drain Valve | Zero dead space with a flat flange clamp |

| Condenser | Single-cooling coil design |

| Funnel | Pressure Equalizing |

| Unit Dimensions (LxWxH) | 17"x 18" x 48" |

| Frame Dimensions (LxWxH) | 17" x 18"x 45" |

| Shipping Dimensions | 24" x 20" x 55" |

| Shipping Weight | 140 lbs |